PRODUCTION PROCEDURE

1.Wax Injection

PRODUCTION EQUIPMENT

EMICO has been developing various products for its international client base since 2002, with continuous supplies made to advanced industrial countries such as the United States of America, countries across Europe, Japan, etc.

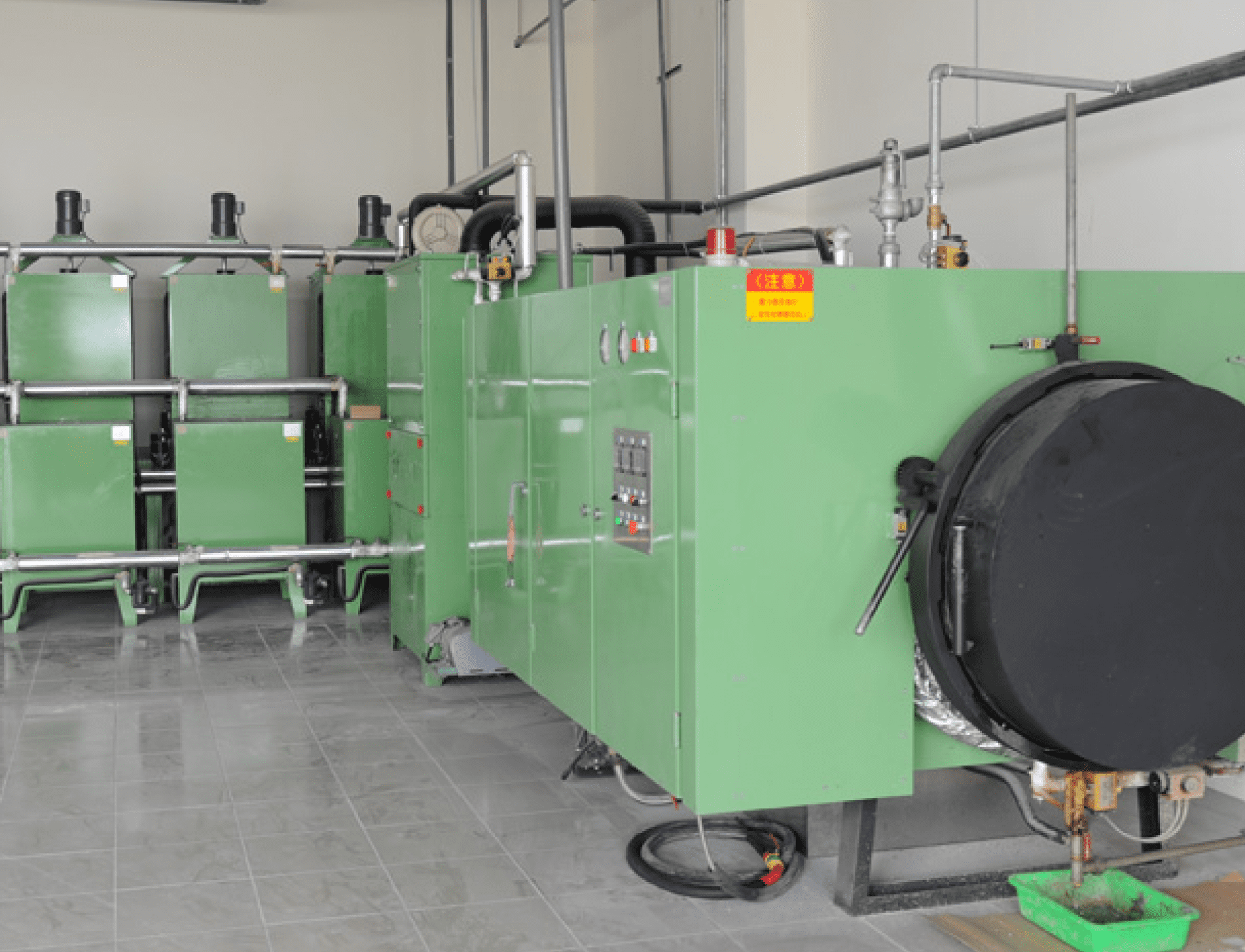

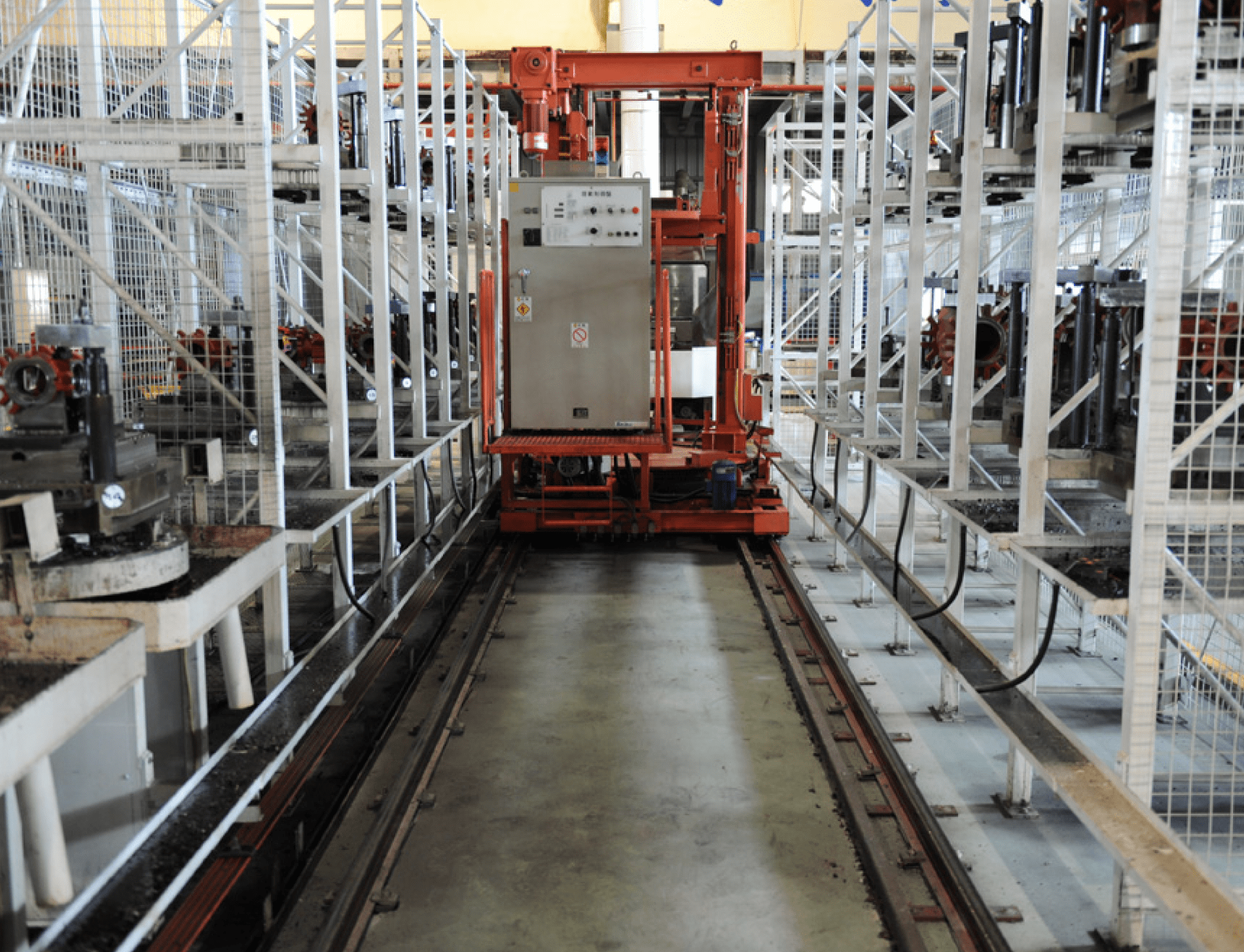

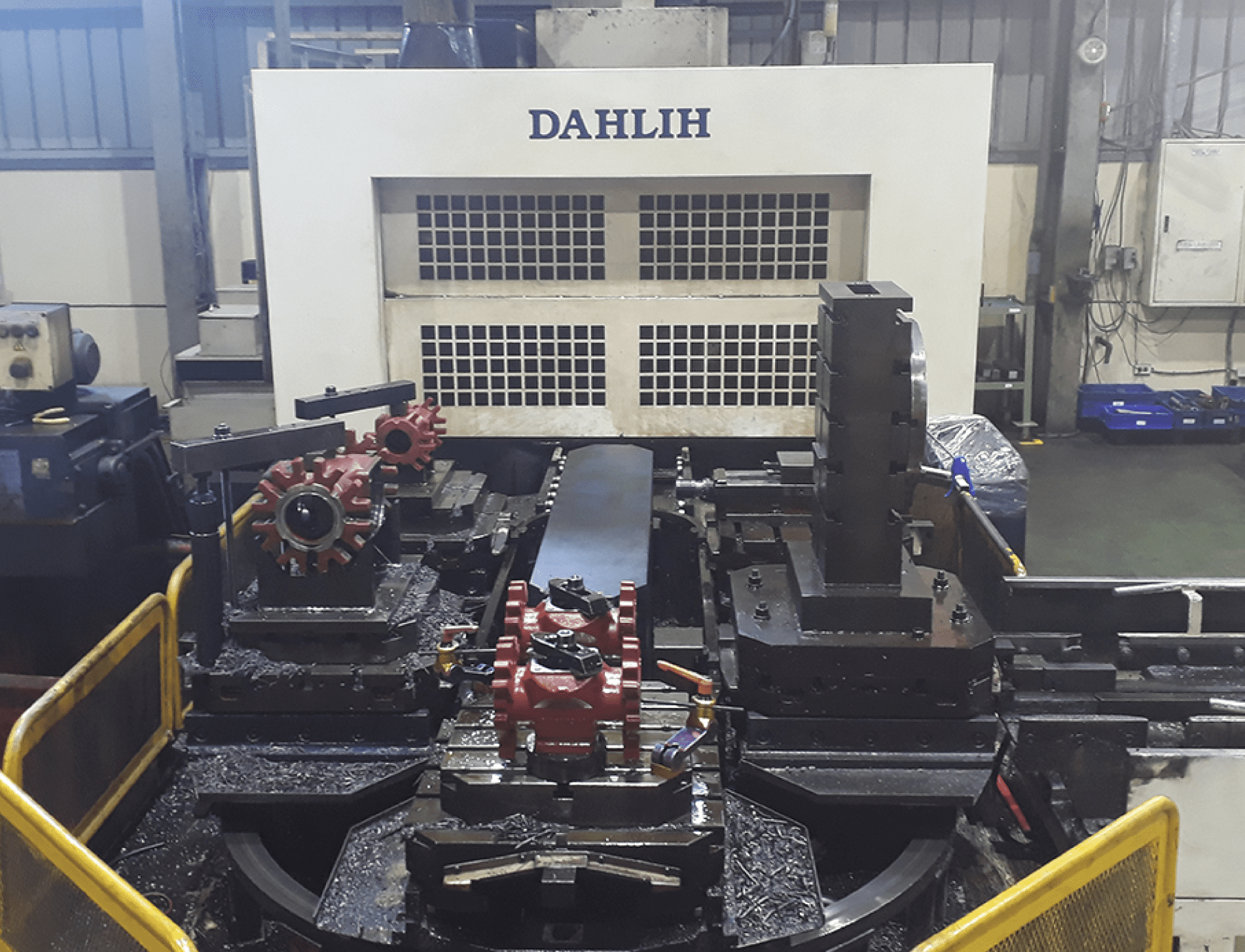

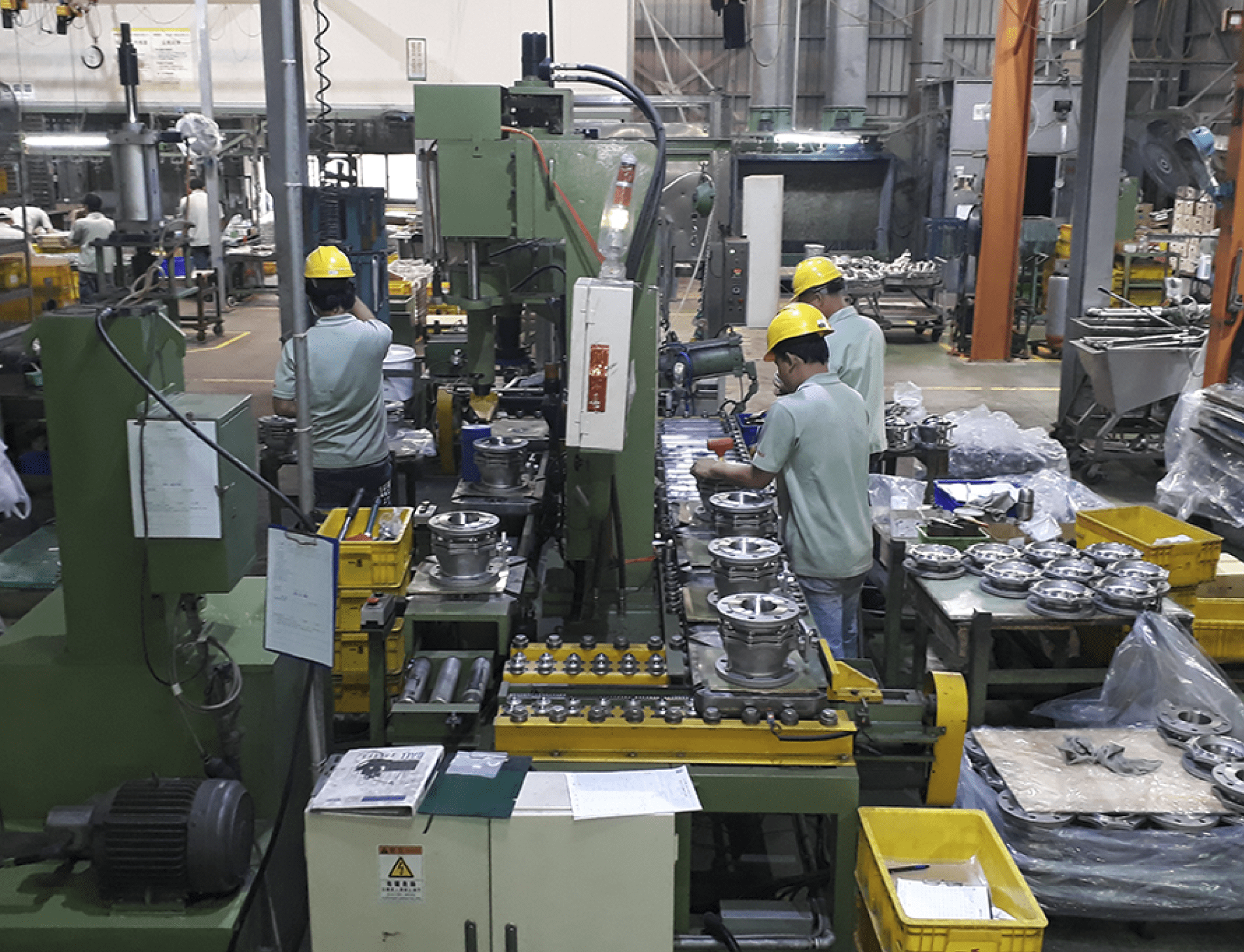

EMICO has cooperation agreements with Mitsubishi Heavy Industries Ltd., Japan, as well as Hitachi Valves, Japan to further improve the stability of production technology and quality. In order to improve product quality and plant capacity, EMICO developed its own in-house foundry for investment castings with fully functional automated production equipment. Along with the investment made in our foundry and our dedicated production management and quality control procedures, we are able to assure and enhance the quality of our well-established product range.

EMICO has cooperation agreements with Mitsubishi Heavy Industries Ltd., Japan, as well as Hitachi Valves, Japan to further improve the stability of production technology and quality. In order to improve product quality and plant capacity, EMICO developed its own in-house foundry for investment castings with fully functional automated production equipment. Along with the investment made in our foundry and our dedicated production management and quality control procedures, we are able to assure and enhance the quality of our well-established product range.

PROFESSIONAL INSPECTION AND TESTING

We have a fully functional quality control laboratory with comprehensive product verification capability. In addition to material composition & analysis, microstructure, mechanical properties and dimensional measurement, we have high-end measuring instruments such as spectrometers, and German produced advanced contact image measurement system, used to inspect, simulate and verify product structure. We have simulation verification equipment capabilities, and great design verification capabilities. (Casting: ProCAST software. Valves: fire test equipment, cryogenic test equipment (down to -196 °C)). EMICO has quality-assurance system certification, supplier certification, and various product verification.

1. Three-dimension coordinate measuring machine

2. Coaxial test bench

3. Contour measuring system

4. Cryogenic test

5. Fire test

6. Helium Leak Detector

7. Hydraulic valve test bench

8. Impact test machine

9. Metallographic microscope

10. Portable alloy analyzer

11. Sclerometer machine

12. Spectrometer analysis instrument

13. Surface roughness analyzer

14. Tension test machine

15. Ultra-low temperature freezer

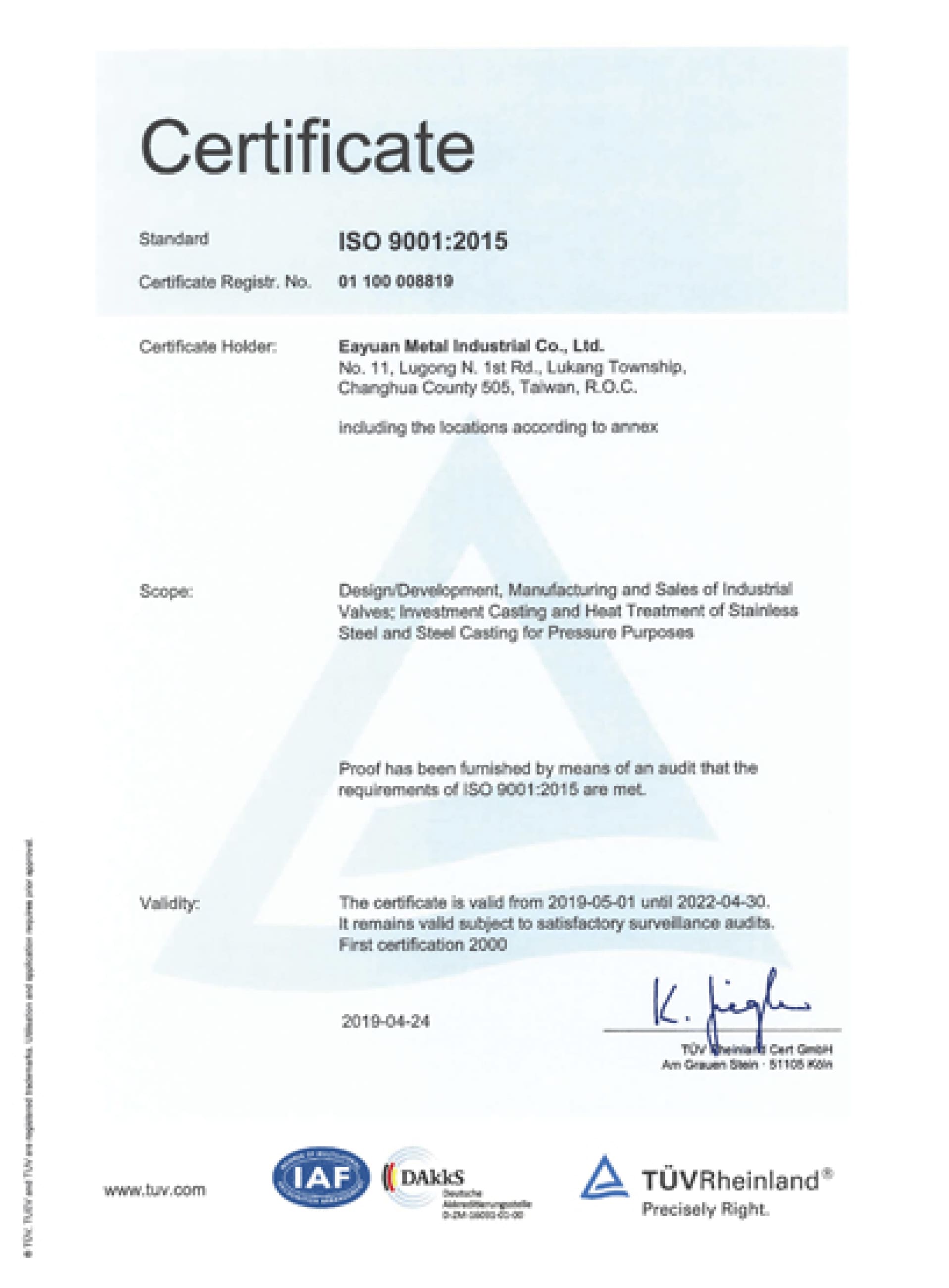

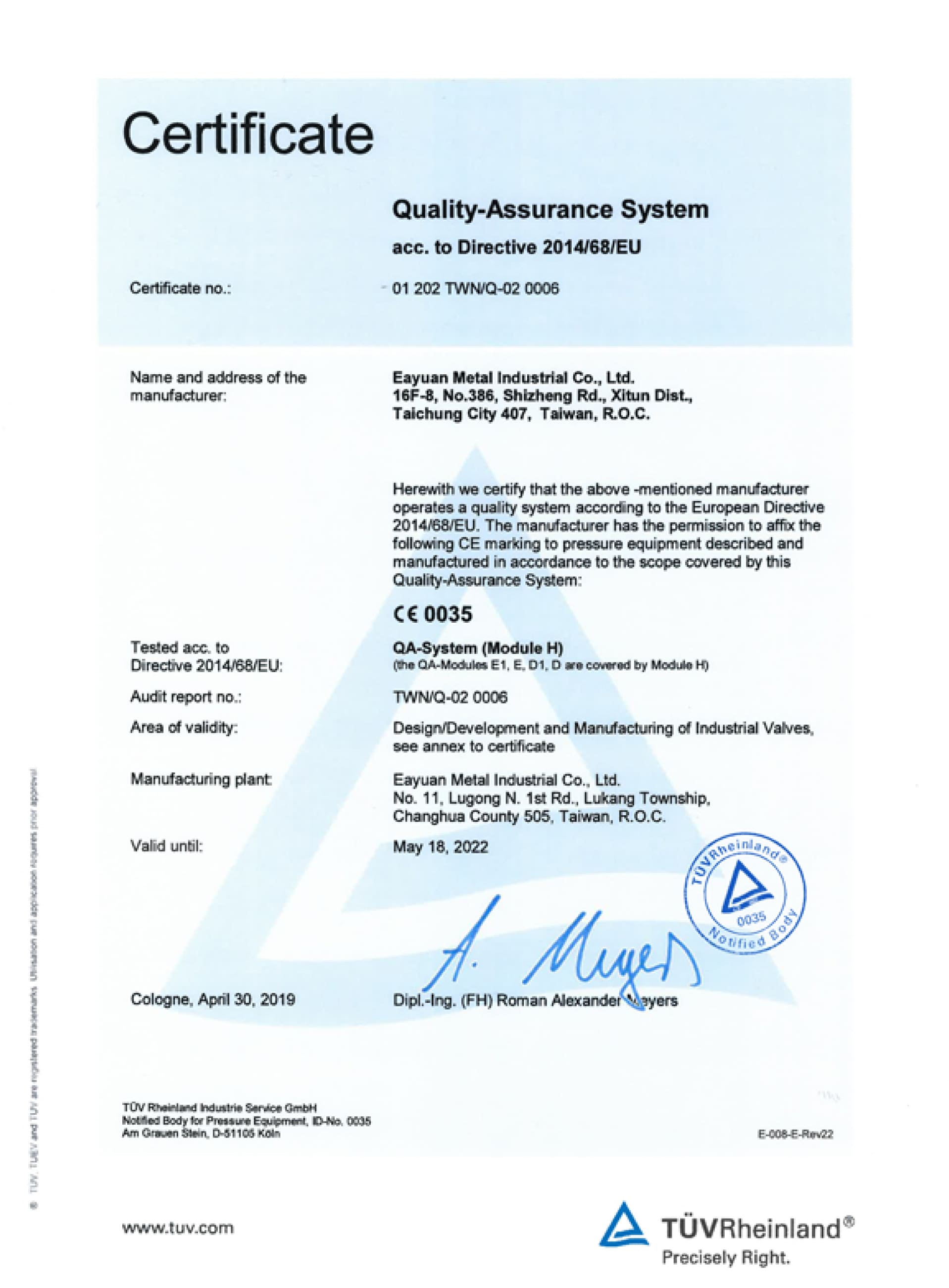

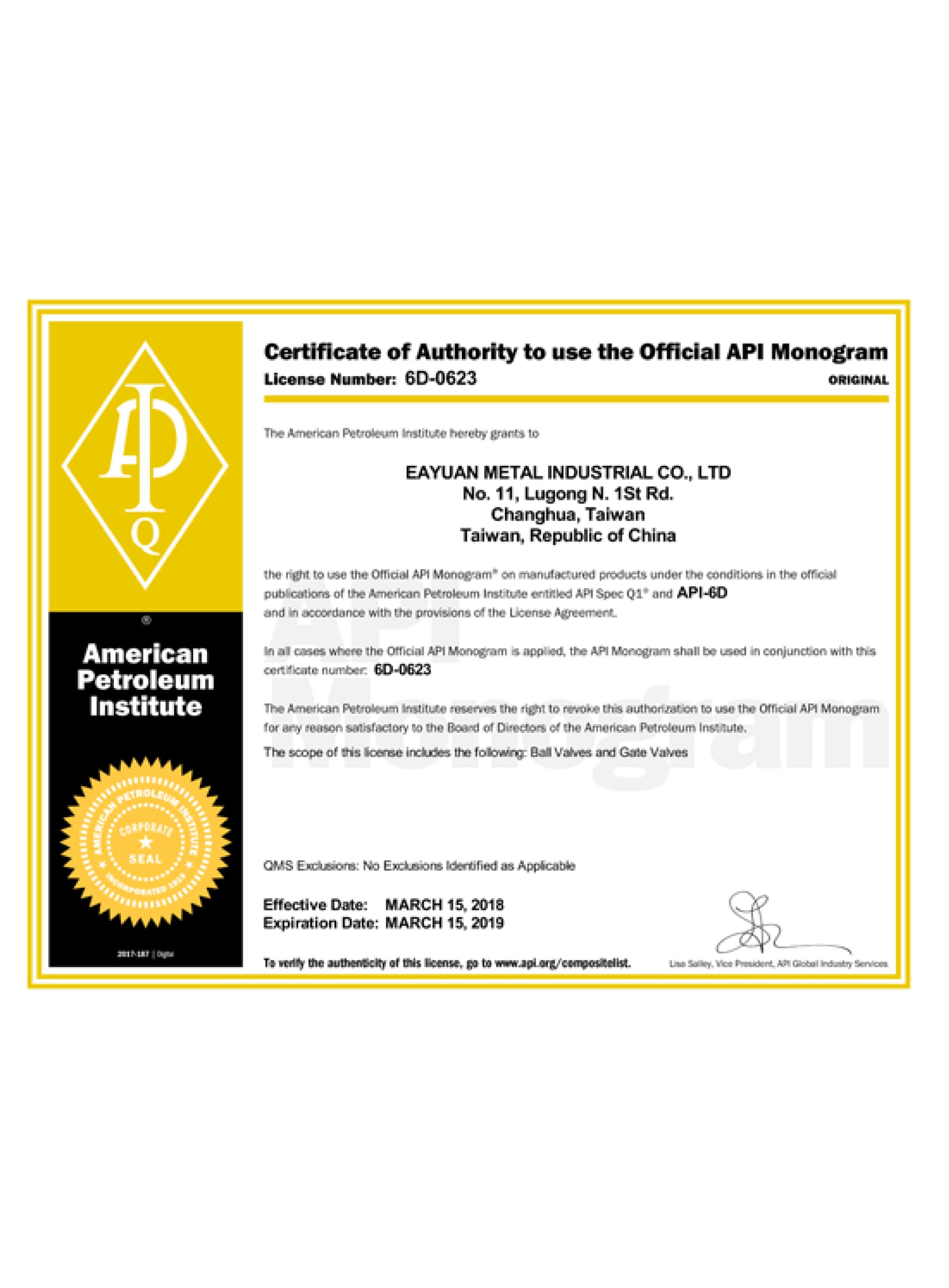

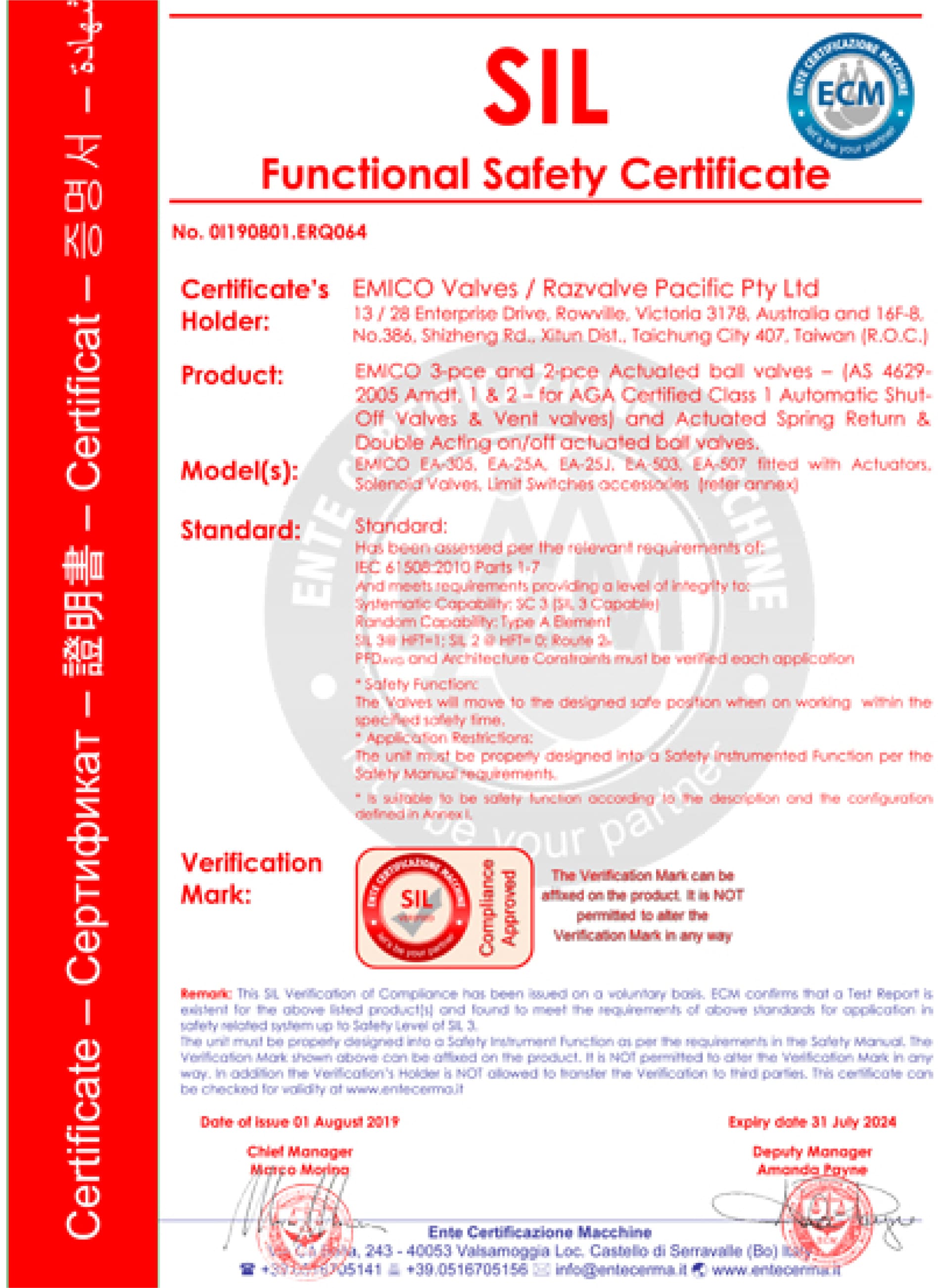

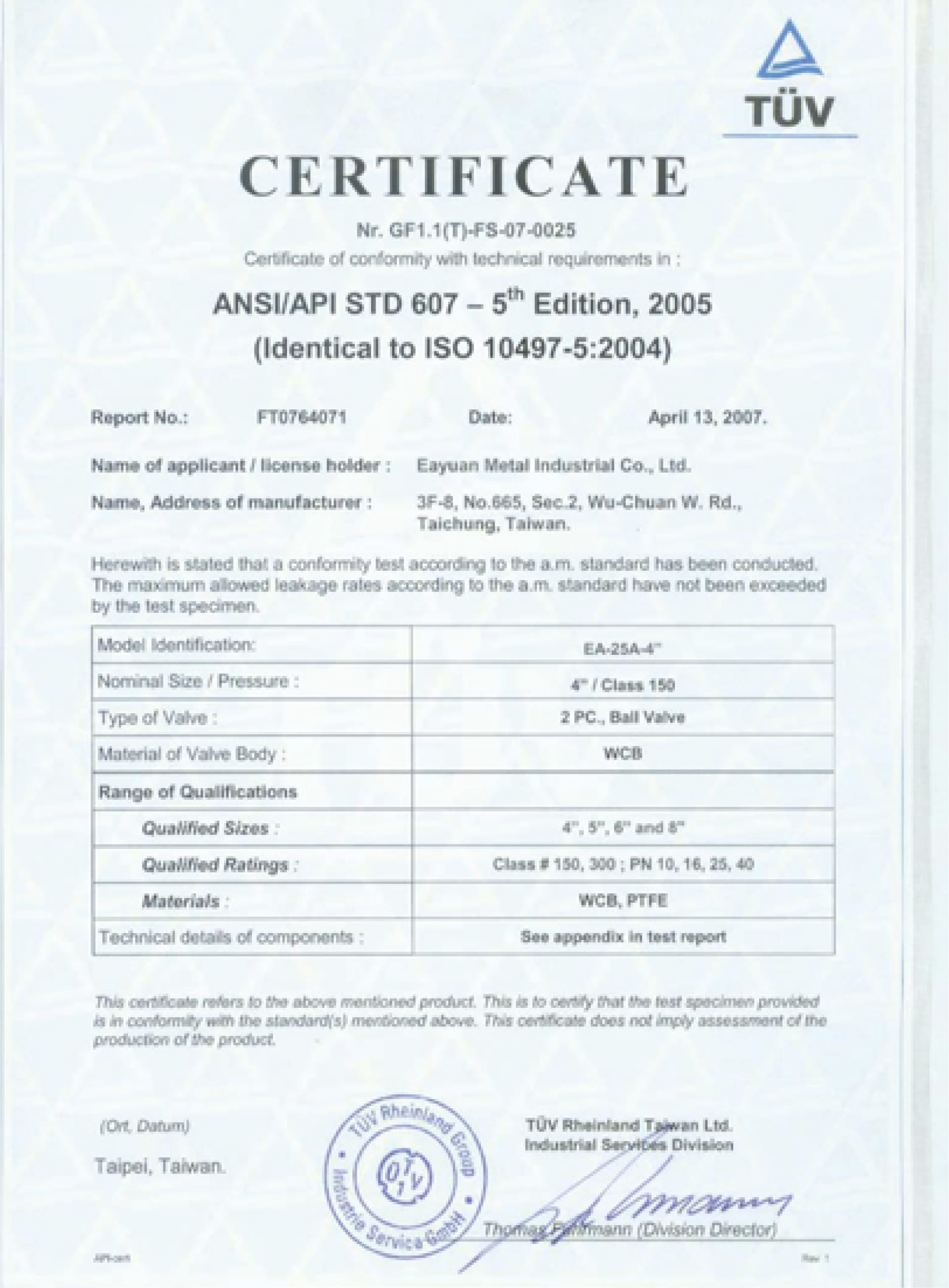

QUALITY CERTIFICATION

Quality-Assurance Certification

ISO 9001

PED CE

API 6D

Product Certification

SIL Certificate

TA Luft certificate

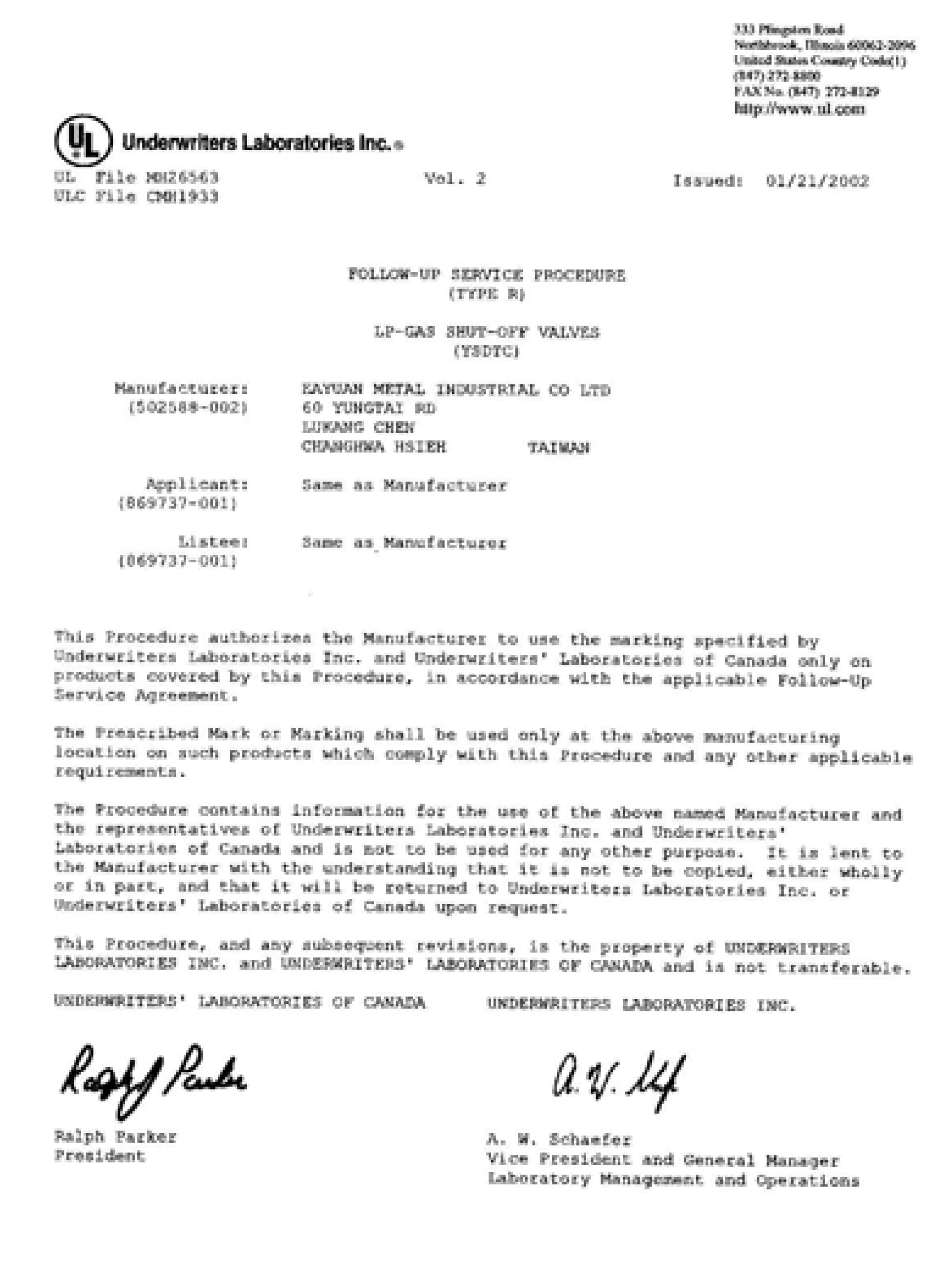

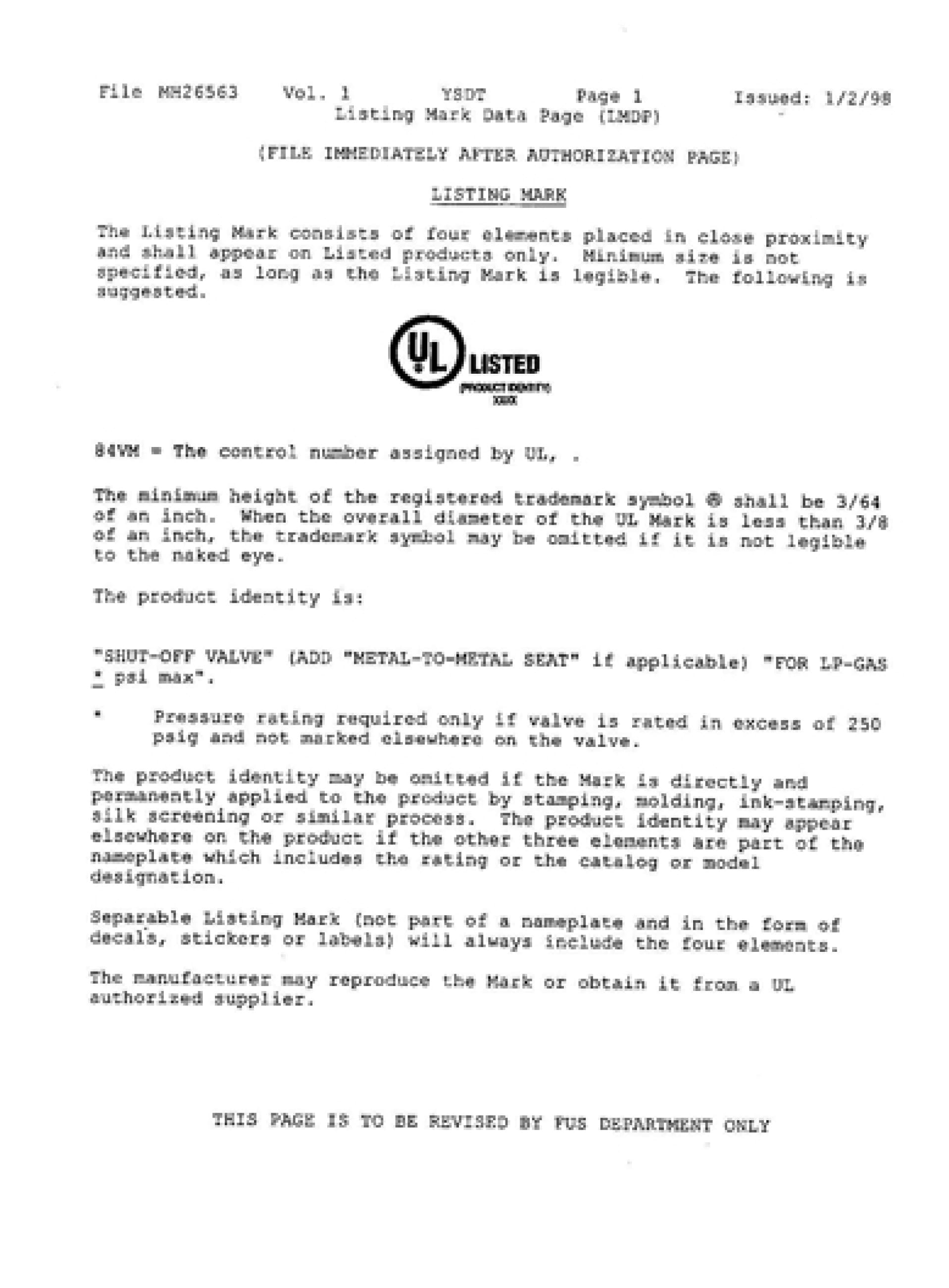

UL

UL

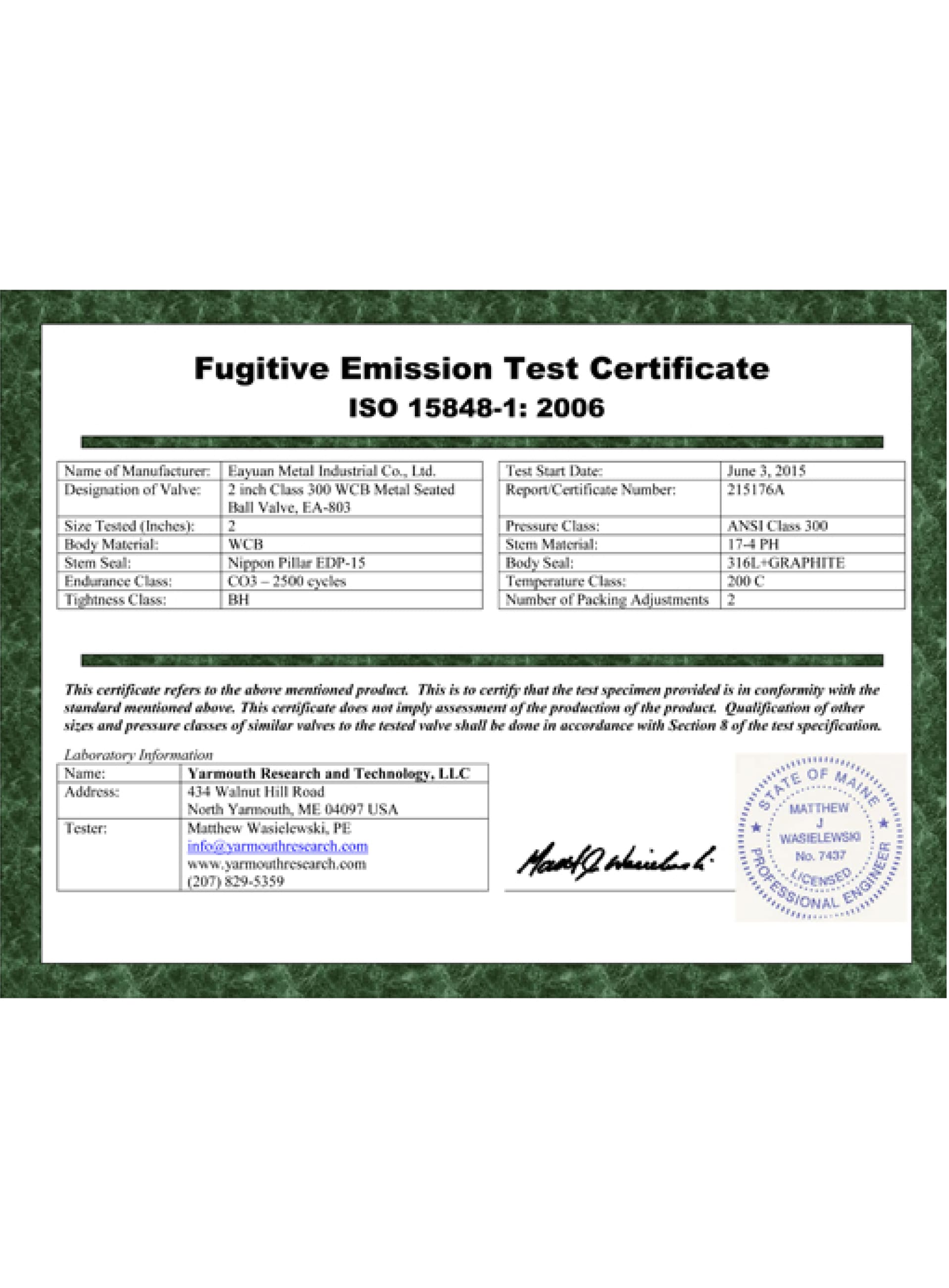

ISO 15848-1 Certificate, CO3

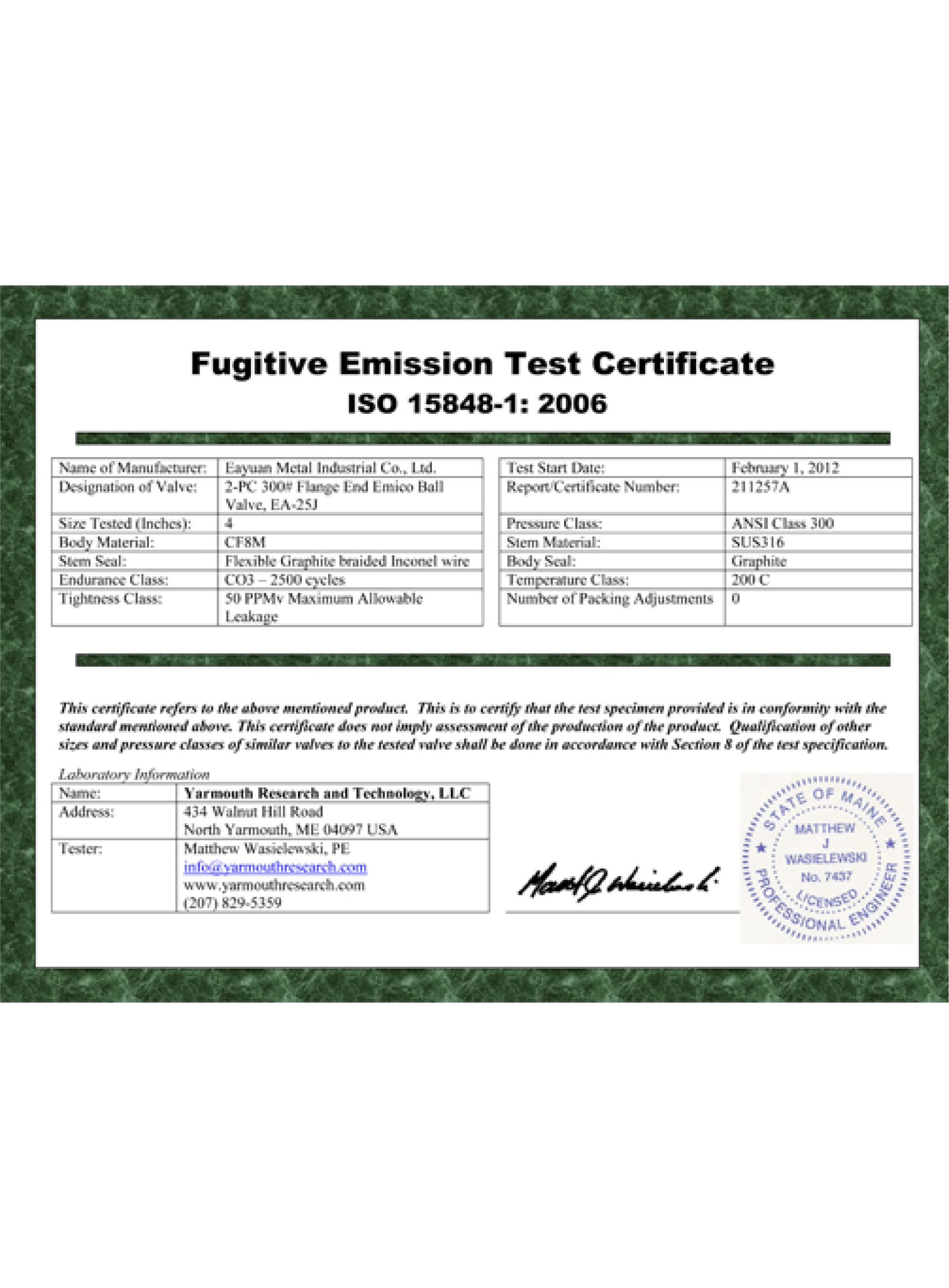

ISO 15848-1 Certificate, CO3

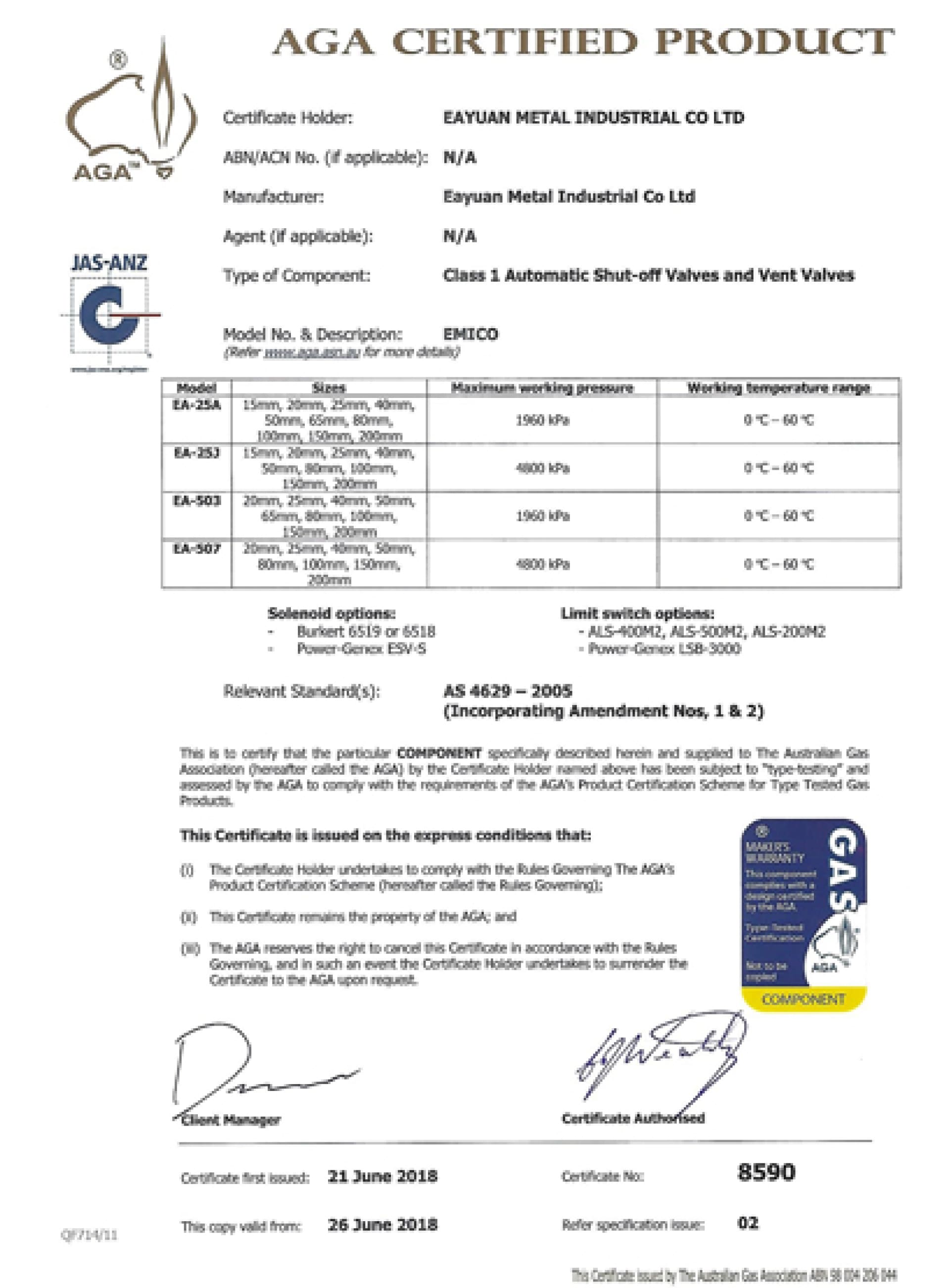

AGA Certificate - Actuated Ball Valve

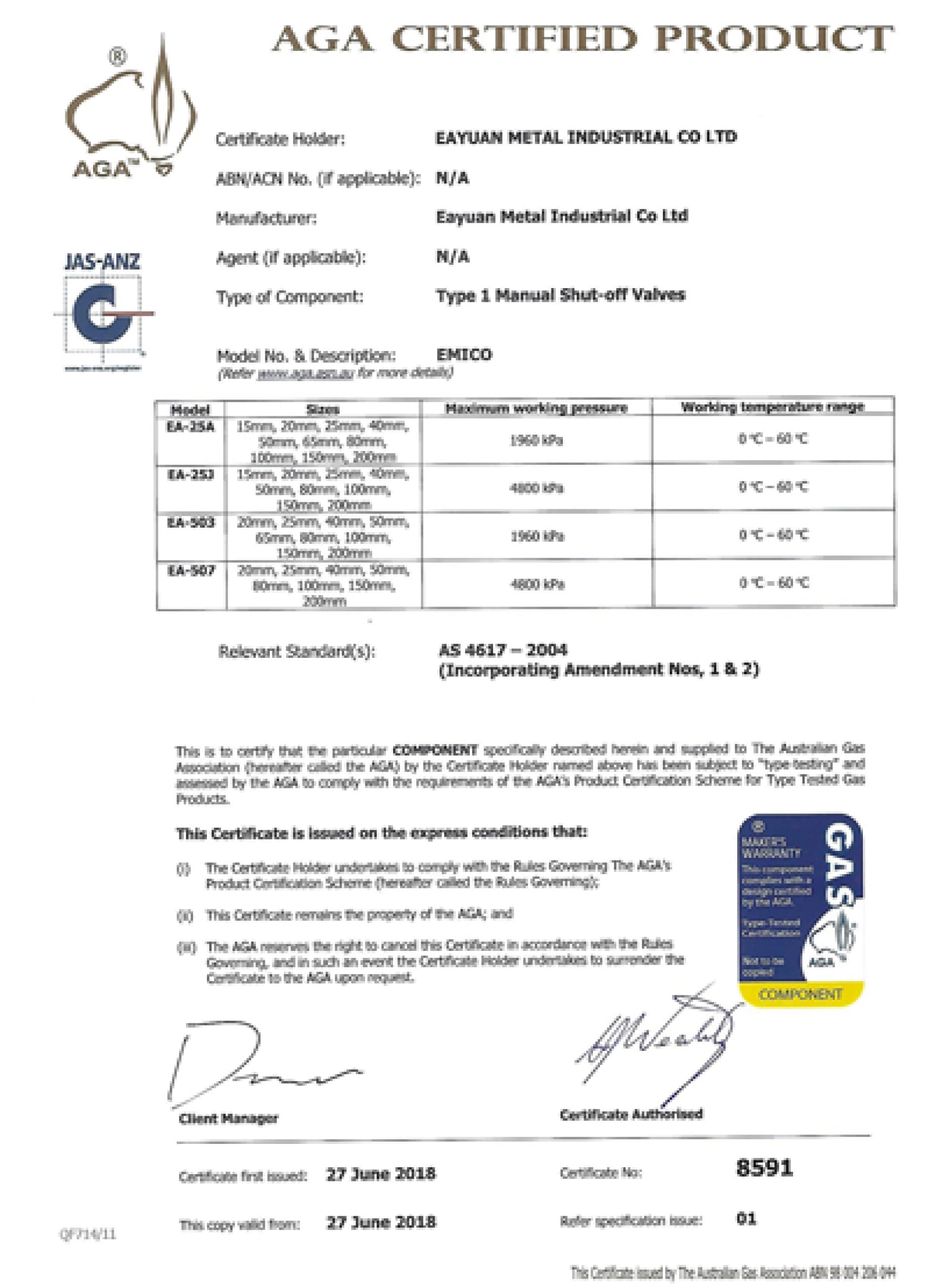

AGA Certificate - Manual Ball Valve

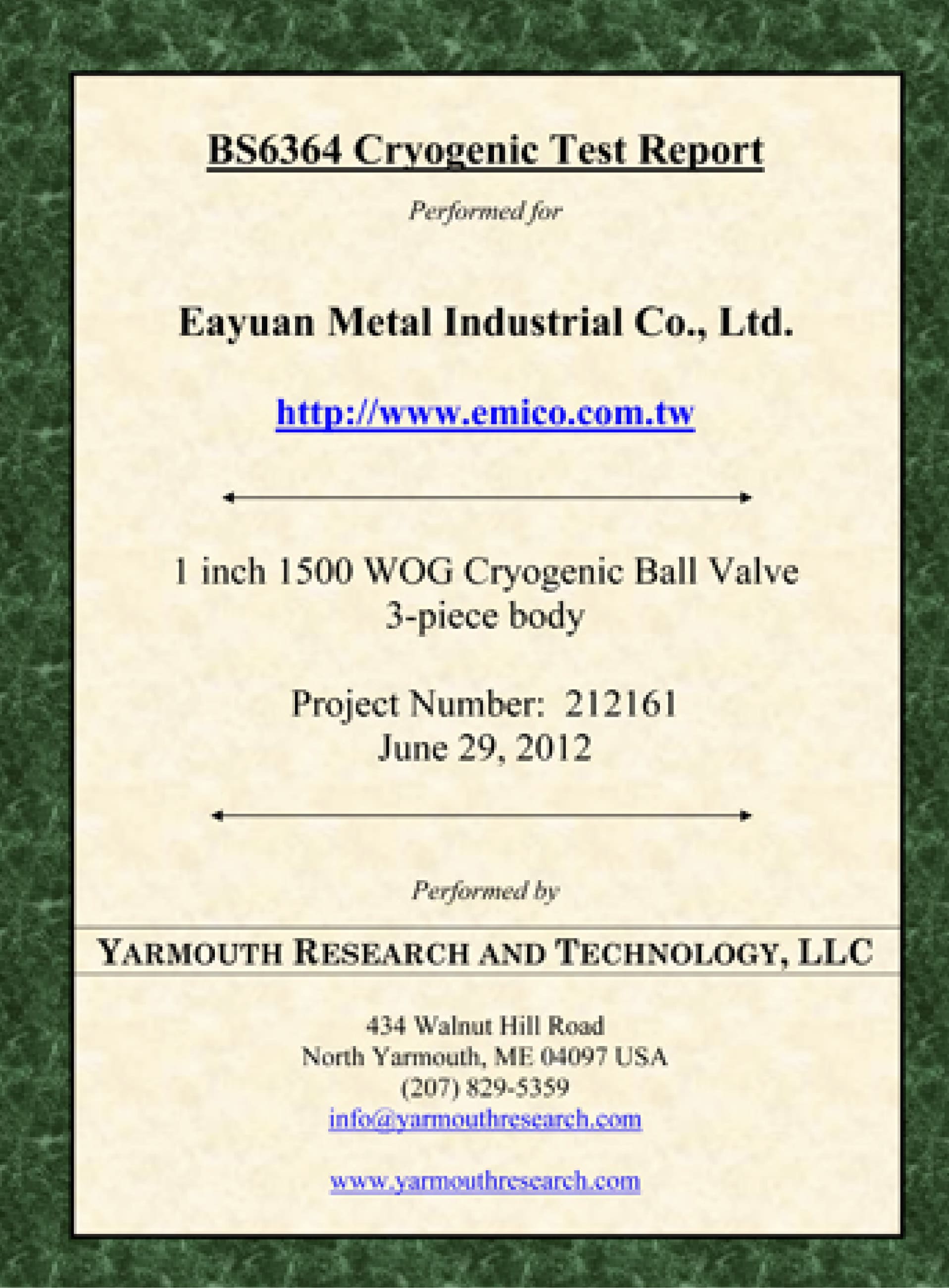

Cryogenic Test Report - BS6364

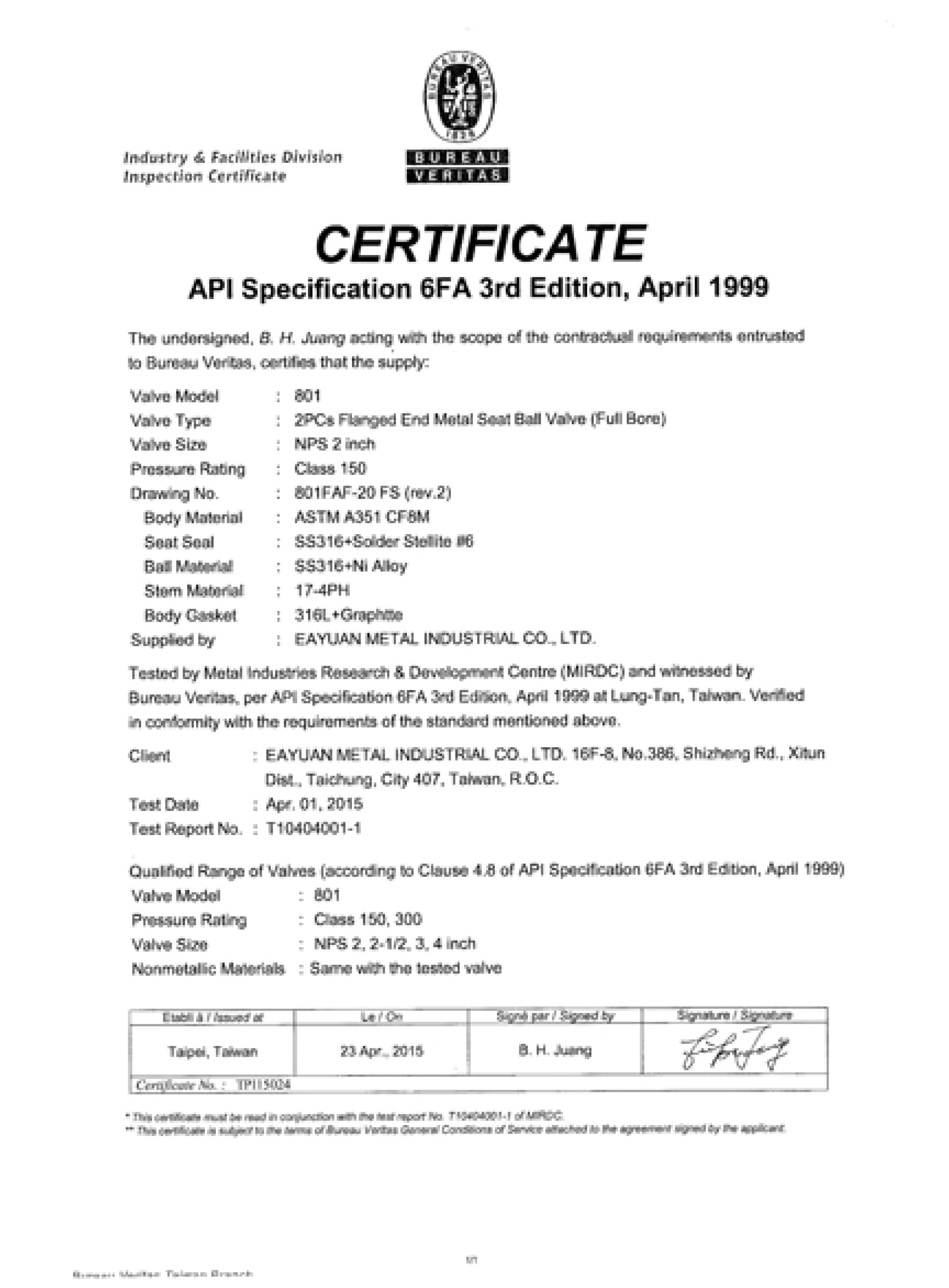

Fire Safe Certificate

Fire Safe Certificate

Fire Safe Certificate